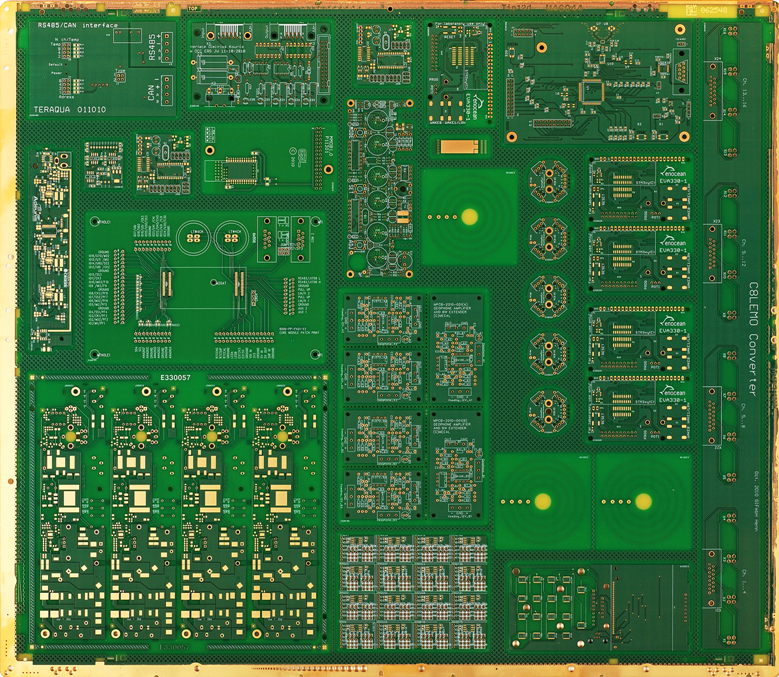

DFM: Production quality starts with the design ??

"Production quality starts with design" is an often-quoted phrase in PCB assembly and the topic of today's "Technology Thursday".

This is because Design for Manufacturing (DFM) has a direct influence on the efficiency of PCB assembly. It speeds up production, improves quality and reduces production costs. ???

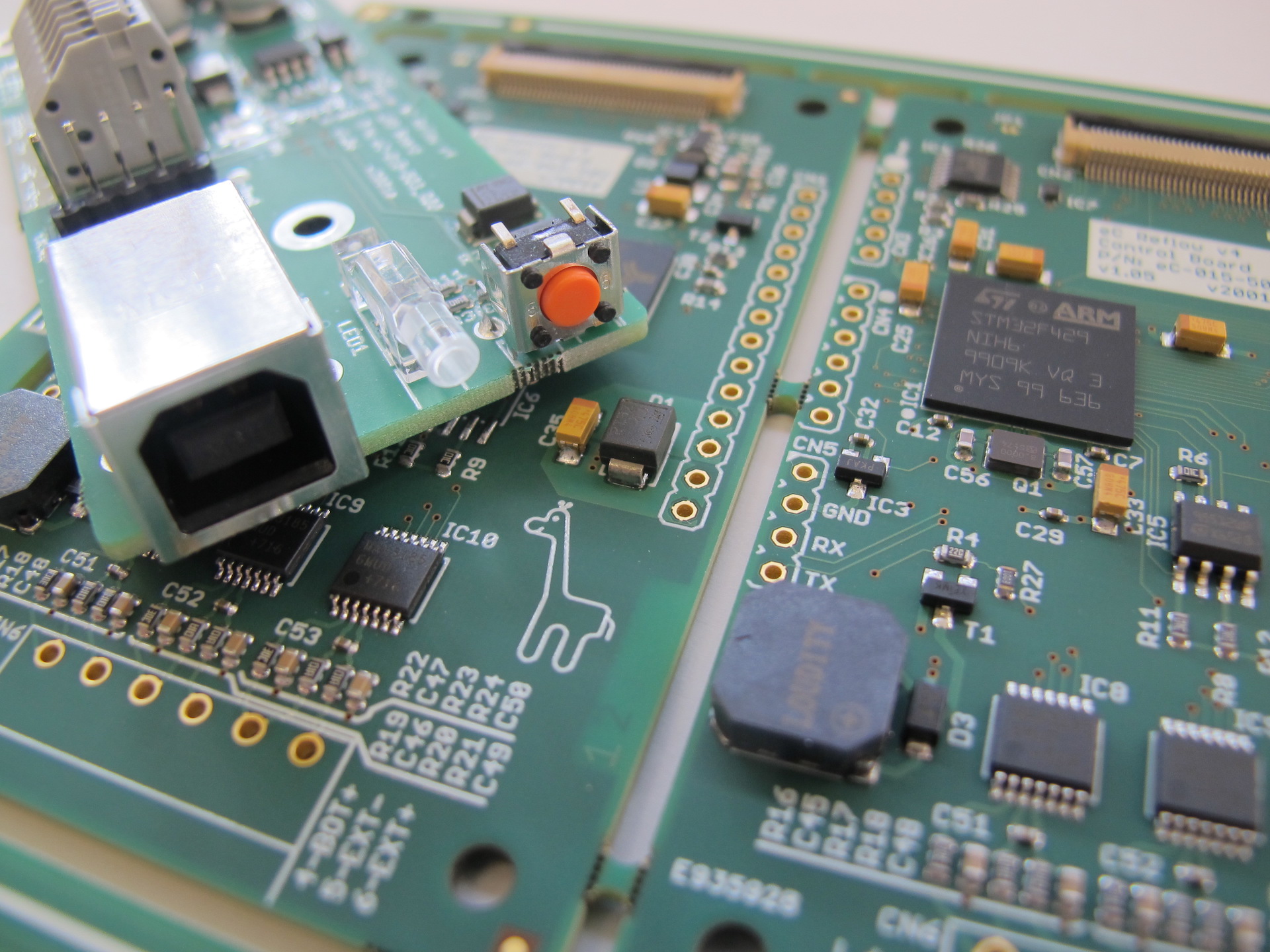

The criteria for PCB assembly in the prototype phase are:

- Positioning of components ?

- Rotation (pin 1) ?

- Size and shape of the solder pads (footprint) ?

- Space for part assembly ?

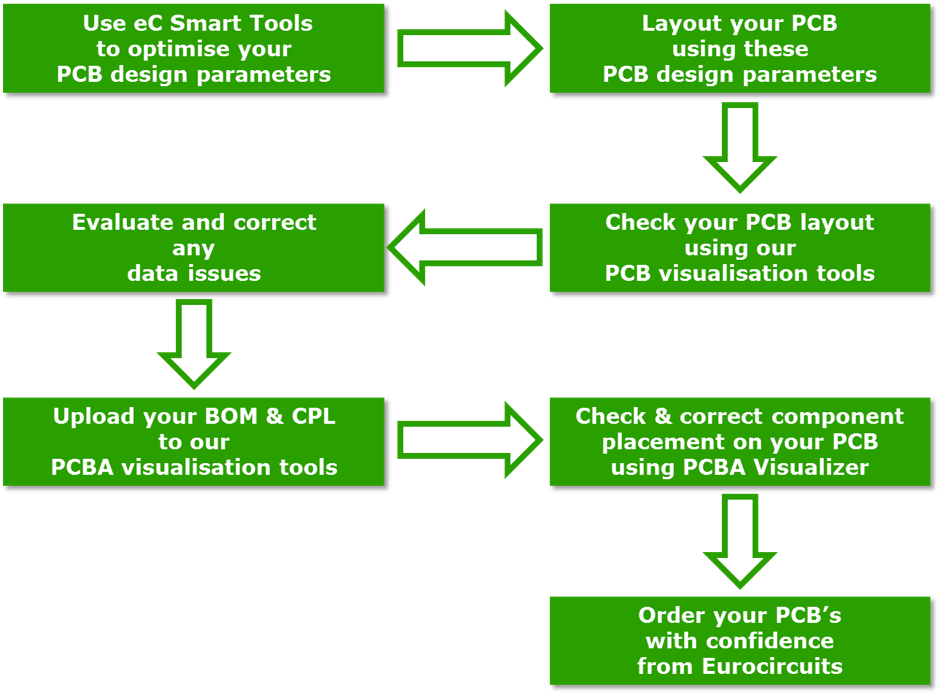

These typical errors can be checked in advance with the Assembly Checker. Our software compares the PCB layout and the component placement list (CPL) and reports deviations and problems while viewing the PCB as an image. ??

It is free to use. All you need is a user account. Check out here how the tool works ?

https://www.eurocircuits.com/ec-smart-tools-user-guides/assembly-checker/

??? The manufacturability of the PCB and the placement of electronic parts are by no means all that matters when designing reliable electronic hardware. Testability, assembly, repairability and recyclability must also be taken into account. The term Design for Excellence describes all these aspects together.

#eurocircuits�#PCB�#PCBdesign�#pcbassembly�#pcbmanufacturing