Delft Hyperloop uses Nijkerk Electronic equipment for battery systems

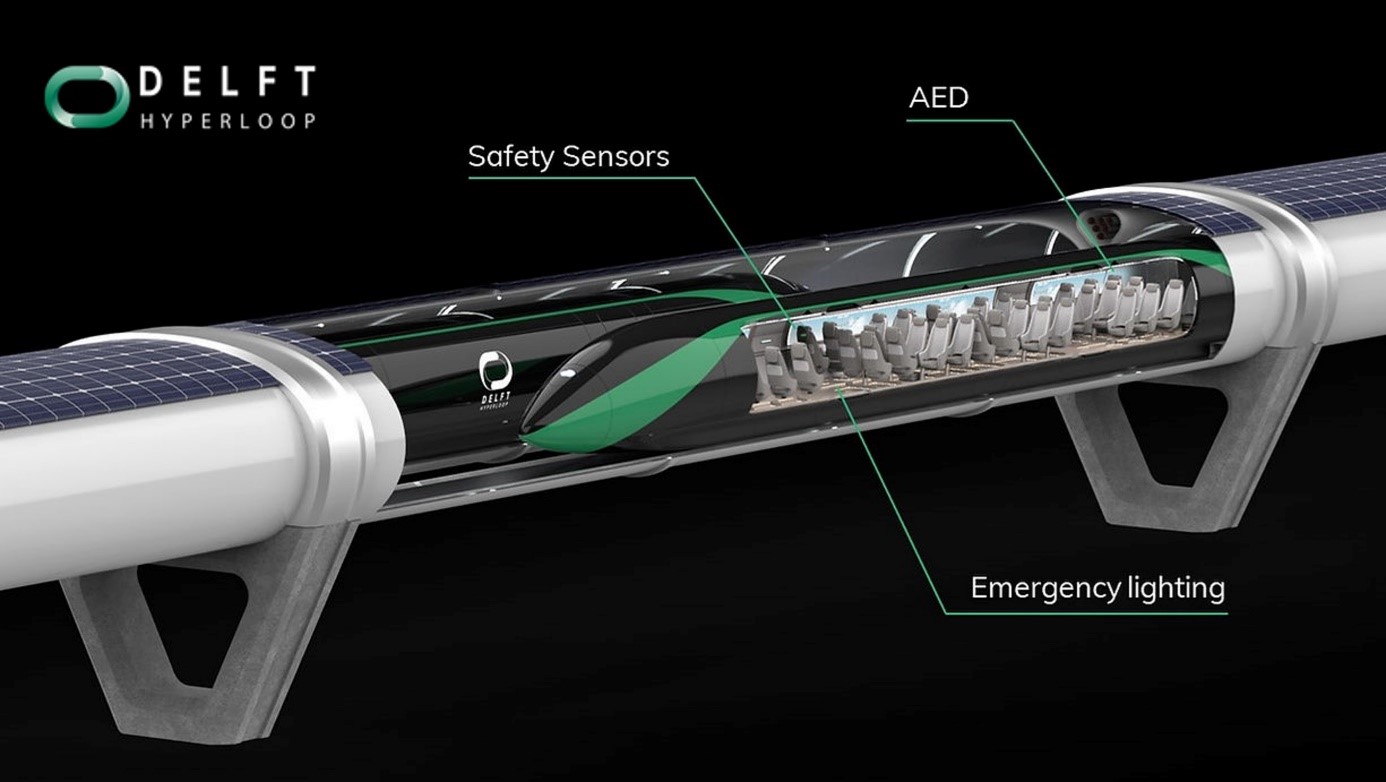

Delft Hyperloop is developing a climate-neutral, scalable hyperloop system. A hyperloop is a new form of transportation in which a pod floats through a vacuum tube and is propelled by magnets. This eliminates rolling and air resistance, allowing it to achieve speeds of up to 1000 km/h, making it a fast and energy-efficient mode of travel. Delft Hyperloop was founded in 2016 by a group of students from the Delft University of Technology and is still run by students as a non-profit organization. They are participating in a competition with student teams from all over the world, thus promoting the development of a hyperloop network through new technologies and knowledge. Nijkerk Electronics supports Delft Hyperloop by supplying switches and contactors for the pod.

Goals and challenges

Last year, the sixth Delft Hyperloop team won the Complete Pod Design Award during the European Hyperloop Week. This year, the seventh team is also taking crucial and challenging steps to advance the technology and aim for victory once again. The team aims to achieve full levitation for the first time, with no contact with the track whatsoever. In addition, the team is developing a completely new propulsion system that has never been made on this scale before. This propulsion system will be integrated into the pod, making the infrastructure simpler and more scalable. As a result of this new propulsion system being on the pod, a lot of extra power is needed. A challenge, as this power needs to be generated and distributed in a safe and secure manner.

Rincon Power switch

Since a lot of power is required, batteries are distributed to four enclosures. Safety and modularity are an important factor so the team decided to install a separate switch on each enclosure, providing an additional layer of safety to the system. Mirko Donkelaar , lead Sense & Control of team Delft Hyperloop, on why they’ve chosen the 400A High Voltage Battery Disconnect (HVBD) from Rincon Power: ‘Our batteries can deliver a current of 150 Amperes at 450 Volts. Most switches designed for such high currents can only handle up to about 50 Volts. This is because they are built around the automotive industry, where voltages don’t reach as high. Fortunately, this switch can easily handle this voltage and current. We are very happy with the Rincon Power switches as they are easy to connect and use.’

Gigavac contactors

With the new developments, the batteries have become significantly larger, and the battery management and charging capabilities have been expanded. Mirko Donkelaar: ‘Contactors are essential to safely deliver power to the correct location in the system without jeopardizing other subsystems. In addition, we use these contactors in our onboard charger for this year. With these contactors, we ensure that the charger can charge multiple battery packs separately’. The GV200, P125, and P105 contactors from Gigavac were chosen because they need to operate at sufficient current and voltage values, while keeping weight and dimensions to a minimum.

Great collaboration with Nijkerk Electronics

Mirko Donkelaar is very satisfied with the collaboration with Nijkerk Electronics. ‘The collaboration with Nijkerk Electronics is going very well. With their expertise in the field of high-power electronics, which we have dealt with a lot this year, they have been able to greatly assist us in our project.’

Phase Control with Galvanic Isolation

Phase Control with Galvanic Isolation  De Itech IT6600C regeneratieve bi-directionele DC voeding

De Itech IT6600C regeneratieve bi-directionele DC voeding  SkelGrid 2.0: Flexible, Scalable, and Easy-to-Maintain with Integrated Master Controller and Modular Switchgear by Skeleton

SkelGrid 2.0: Flexible, Scalable, and Easy-to-Maintain with Integrated Master Controller and Modular Switchgear by Skeleton  Tektronix unveils SignalVu Spectrum Analyzer Software Version 5.4 for analysis of up to eight simultaneous signals

Tektronix unveils SignalVu Spectrum Analyzer Software Version 5.4 for analysis of up to eight simultaneous signals  New AC/DC Din Rails in Slim Design by RECOM

New AC/DC Din Rails in Slim Design by RECOM