Holy Stone has developed the MLCC SuperTerm Series

Holy Stone has developed the “Super Term” Series (TX suffix in the part number), which incorporates a “cushion layer” in the termination structure. This construction effectively absorbs external forces, reduces the incidence of cracking and improves overall product reliability. SuperTerm product applications include: high temperature, automotive, power circuits and other critical end products with extreme processing conditions.

Due to the brittle nature of the dielectric material, multi-layer ceramic capacitors are more prone to the excesses of mechanical stress than other components used in surface mounting. Internal MLCC cracking can result in serious failure modes. If ceramic capacitors are subjected to severe mechanical stress, a bending crack may occur. This crack can run through two or more electrodes of opposing polarity and result in a short circuit. Typical bending cracks are shown below.

In the worst case scenario, these short circuits may lead to the MLCC overheating and catastrophic failure. Standard termination construction may result in ceramic cracking during PCB bending, vibration, Depanelizing, etc.

Actual Examples

Failure Mode Type 1

The failure mode results from PCB bending forces. These cracks may not be visible on the MLCC surface. Cross sectional analysis is required to identify these internal cracks.

Failure Mode Type 2 (wetting greater than 2/3 of thickness)

MLCC cracking frequently occurs during the circuit board depanelizing process. The root cause is knife (blade) vibration during the process

SuperTerm Polymer Termination

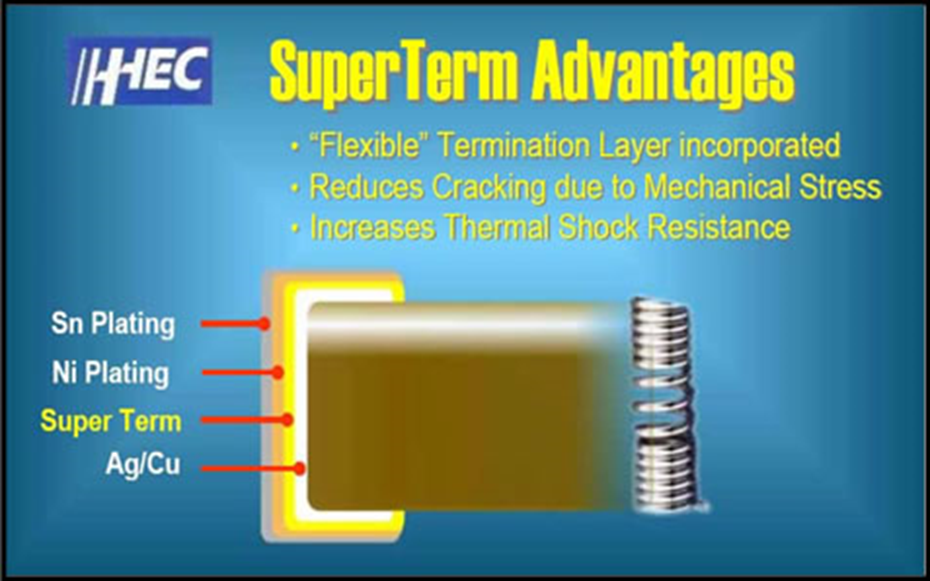

Holy Stone has investigated ways of improving the bend performance of its product, resulting in the availability of a new termination system. The result is an additional Polymer termination material specifically designed to absorb greater levels of mechanical stress thereby reducing capacitor failures associated with mechanical cracking.

The additional termination system is a Silver loaded epoxy polymer. It is applied using standard equipment, cured at 180°C in air and electroplated with Nickel and Tin, over the top of the standard sintered Silver/Copper termination. It is the flexible nature of the cured polymer termination which absorbs the strain between the PCB and the capacitor.

The Silver loaded epoxy polymer is applied to the capacitor ends in the form of a paste. The capacitors are ‘dipped’ into the paste using a controlled process/equipment. The paste is maintained at a viscosity of 40 to 60 Pa.s and a solids content of approximately 75%.

SuperTerm effectively prevents ceramic body cracking during extreme mechanical stress as simulated by this test. SuperTerm failures resulting from destructive bending test tend to occur in the OPEN mode and not the short circuit mode typical of standard termination failures. The SuperTerm cushion layer material is a ”polymer silver” material and can be seen in the photo.

Reliability/Durability Comparison

During destructive bending test, the PCB is subjected to bending until capacitor failure. With SuperTerm there is no cracking damage in the ceramic.

Make your selection of the standard Holy Stone ceramic capacitors program in our online catalogue on our website.

Or contact Nijkerk Electronics for SuperTerm MLCC.