Ultracapacitor-powered Start-stop Systems in Passenger Cars

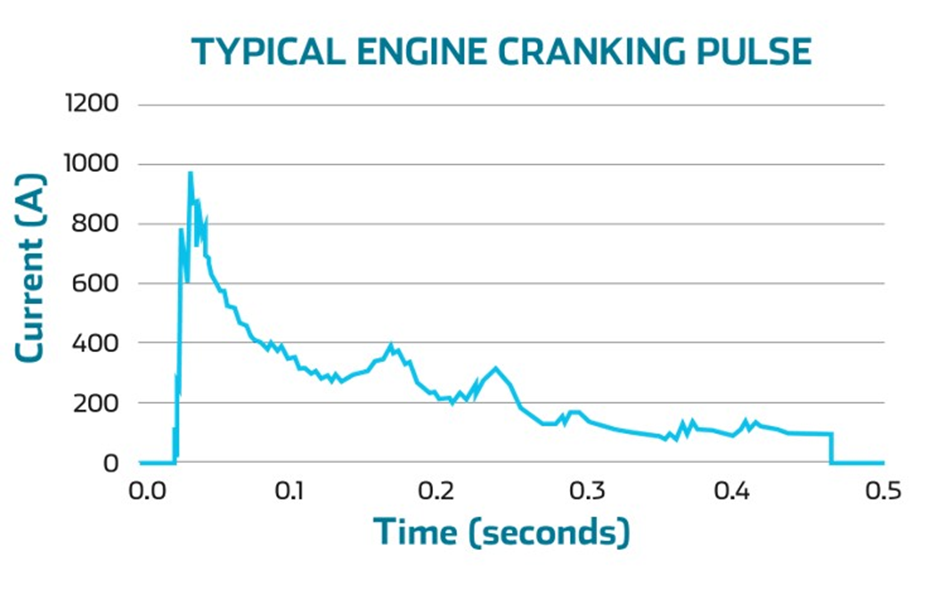

Start-stop systems in today’s passenger cars are almost always powered by lead-acid or AGM (Absorbent Glass Mat) batteries, but the relatively high cranking power and frequent start-stop cycles degrade batteries quickly. In addition, poor low temperature performance limits the functionality of battery-based solutions. From an environmental standpoint, lead-acid batteries are an unnecessary problem – one that can be solved with ultracapacitors.

Ultracapacitors are vastly superior to batteries in engine starting solutions. They have:

- Significantly higher power density compared to batteries, which makes ultracapacitors ideal for engine cranking.

- Full power performance even at -40 degrees celcius/fahrenheit.

- 1 00 000+ life cycles and no maintenance requirements, meaning ultracapacitors will easily last the entire lifetime of a vehicle.

The Skeleton SkelStart Engine Start Module is already used in trucks and other heavy vehicles and machinery for years, but the passenger car market is adapting slower. Even a Tesla has a lead-acid battery on top of the lithium-ion battery back. With ultracapacitors, the automotive industry can leave the ancient lead-acid technology where it belongs, to the past, and step to the future.

Skeleton is working with a number of automotive companies who are making great strides to hybridize and electrify the industry. Ultracapacitors are a big part of the solution, whether we talk about engine starting, replacing the lead-acid battery, or even providing fast charging and enough range to cover daily drives for an electric car. Together with li-ion and hydrogen fuel cells, ultracapacitors are the key to a fossil-fuel-free automotive industry.

Checkout the Skeleton website for more information about the Skeleton SkelStart Engine Start Module.