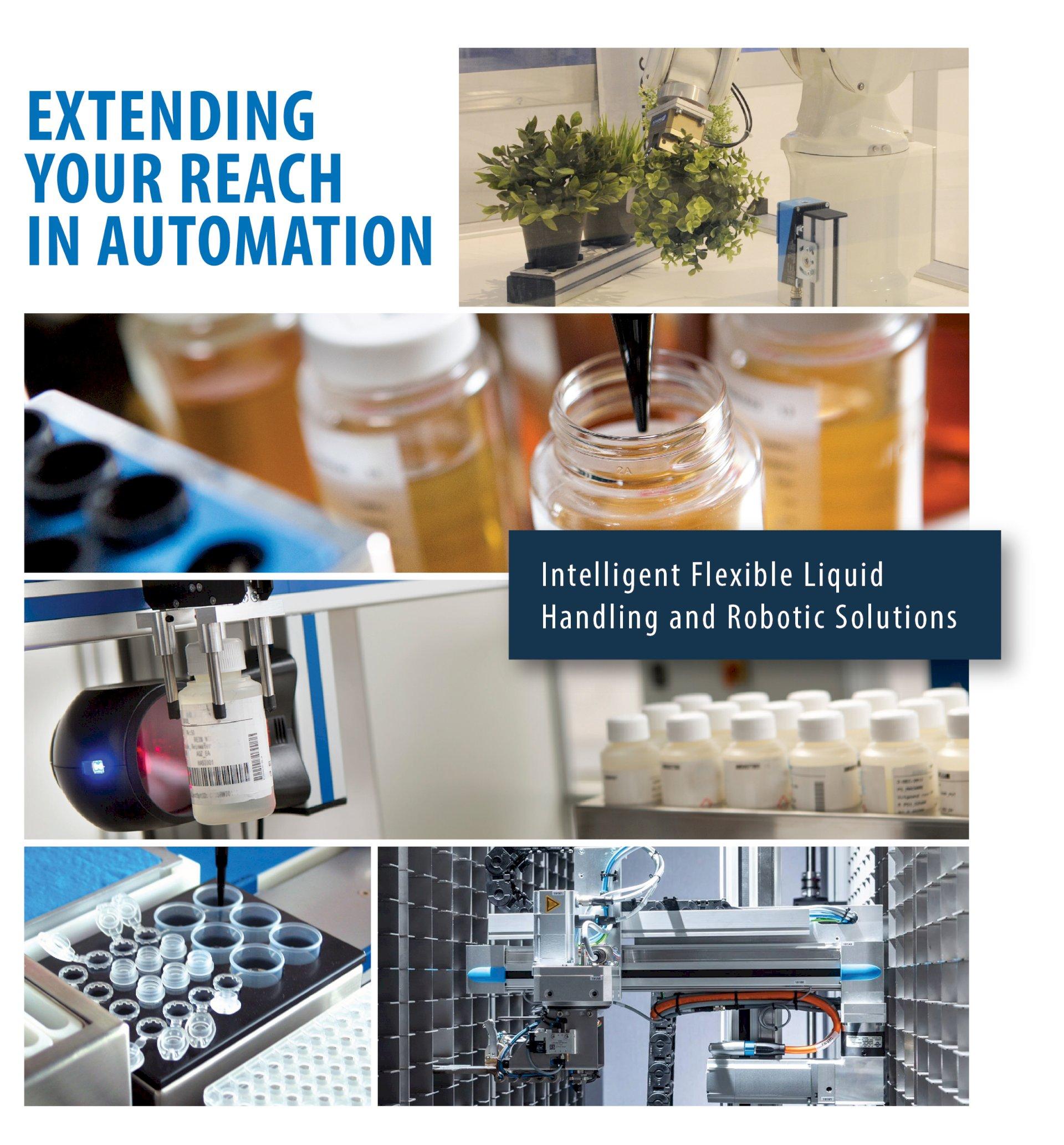

SeedPickers – Seed automation made easy

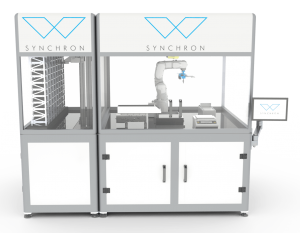

Synchron Lab Automation has developed a fully automated seed picking robot with an automated storage system for processing over 360 SBS microtiter plates. The SeedPicker, part of our AgBio product suite, has been designed for and with our customers in the seed industry. Automating tasks that traditionally have been performed by laboratory staff, have led to an increased throughput and data collection.

Starting from multiple batches with multiple seed types, the SeedPicker can process each seed batch into individual seeds. This process is completely controlled by imaging seeds, scanning barcodes and monitoring applied vacuum during each movement. These single seeds can be placed in microtiter plates for DNA extraction, paper-based germination trays, planting in soil or Rockwool trays or be used for individual seed phenotyping. The SeedPickers can be found in different areas within breeding companies ranging from R&D, seed quality and seed health labs all the way to sowing seeds in greenhouses for field trials.

The Seedpicker

For many processes in the lab, seeds will have to be individualised for analysis. This can be required for DNA extraction, phenotyping, germination or a range of other analysis. The SeedPicker will individualise seeds from multiple batches fully automatically.

The SeedPicker has fixed stackers or can be installed with a fully automated TrayFeeder system. Stackers, conveyor belts PlateFeeders and TrayFeeders are all possible logistics modules for the SeedPicker that proved either the necessary capacity or throughput to keep up with demand. These logistic modules help with getting an optimal cycle time between moving seeds from batch containers to the corresponding target plates or trays. An industrial, high precision 6-axis robotic arm is the centre of the SeedPicker and automates all movements and transfers. The gripper tool has multiple functions which include a plate gripper, interchangeable picking tools, barcode scanner and liquid handling options. Picking seeds is done one by one, each time with the highest possible accuracy and control.

Other AgBio products found in the AgBio product portfolio

Our DNA extraction solutions can purify DNA up to 40.000 samples per day, using magnetic beads. This throughput is accomplished by processing the samples in a semi-serial processing fashion, rather than the traditional parallel processing of microtiter plates in a liquid handling robot.

Analysing the germination process of your seeds can be a time-consuming task which often relies on human, visual interpretation and manual data processing Using robotics in combination with automated imaging and analysis, our Germination systems can fully automate the monitoring and analysis of your germination processes.

All our systems can be linked to your LIMS (Laboratory Information Management Systems) system to ensure a smooth and safe transition of data and samples through our robots within your laboratory workflow.

More info via www.synchronlab.com

Automatiseren voor de toekomst tijdens LabAutomation 2024

Automatiseren voor de toekomst tijdens LabAutomation 2024  Veilige cryogene opslag van stalen met uniforme temperatuur.

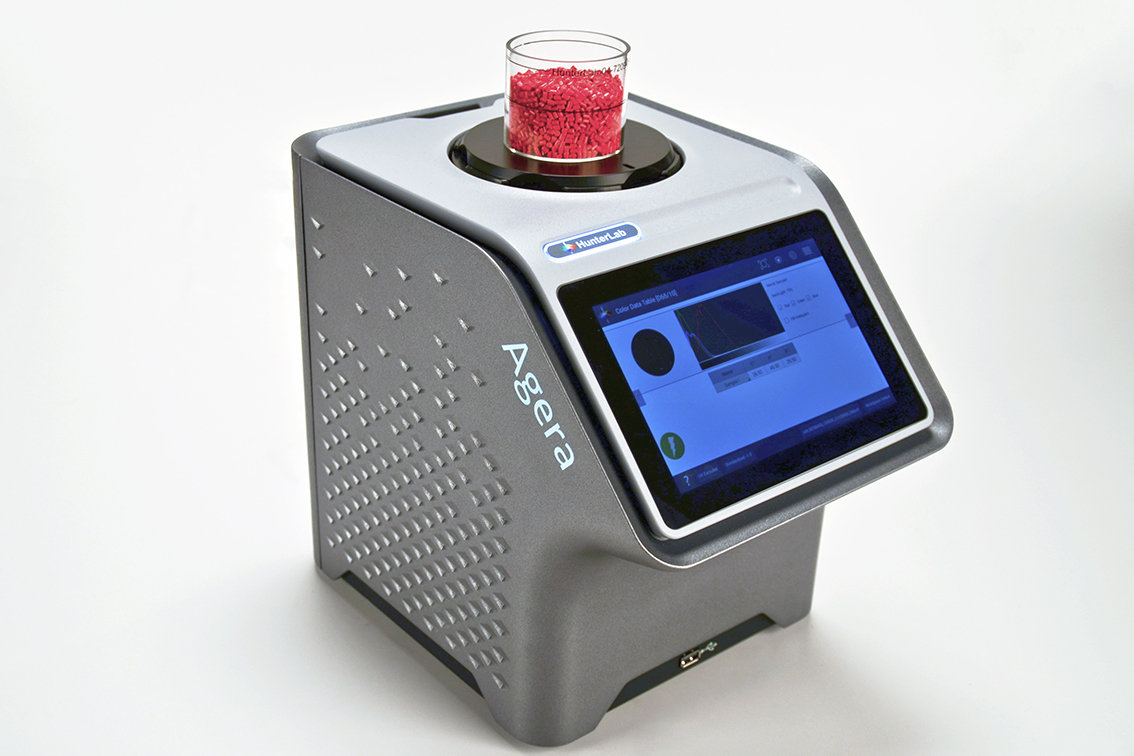

Veilige cryogene opslag van stalen met uniforme temperatuur.  In één meting gelijktijdig kleur en glans meten!

In één meting gelijktijdig kleur en glans meten!  Veilige en betrouwbare ULT-opslag in het veld en onderweg!

Veilige en betrouwbare ULT-opslag in het veld en onderweg!  Automatisch ontdooien van cryovials.

Automatisch ontdooien van cryovials.