Pixpect Inspection After Reflow

?? The world of SMT production: Optimal optical inspection after reflow soldering

In modern SMT production, precise inspection after reflow soldering is essential. This is where Automatic Optical Inspection (AOI) comes into play.

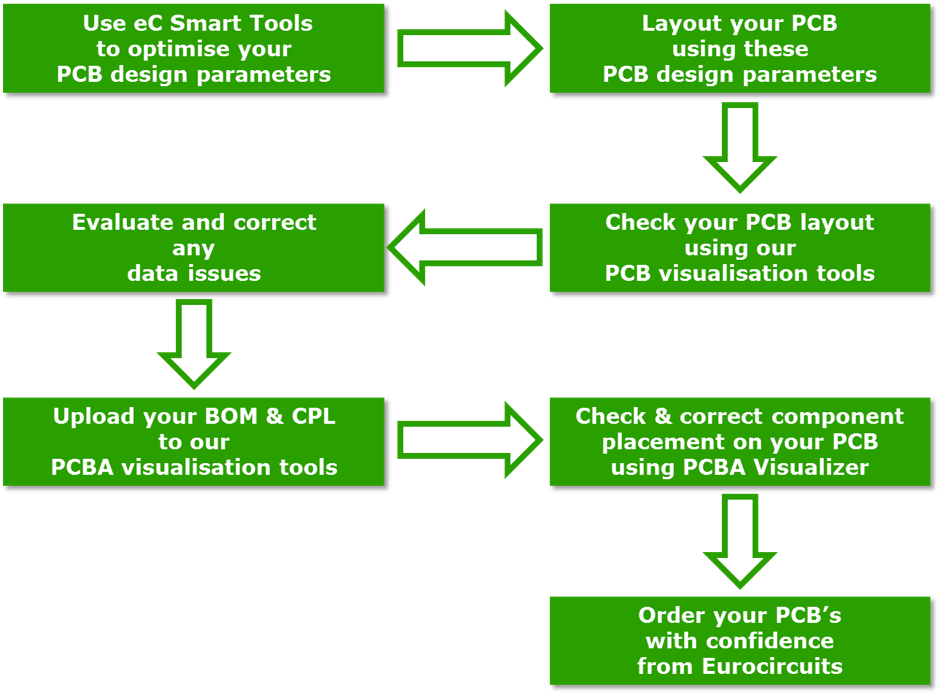

With our production quantities of 1 to 5 PCB Assemblies, a conventional AOI system is oversized and the set-up time is too long. That's why we at Eurocircuits have developed our own inspection system: Pixpect.

Pixpect enables fast and efficient visual inspection of Assembled PCB after reflow soldering. This rapid analysis is particularly crucial in prototype production, where every step counts.

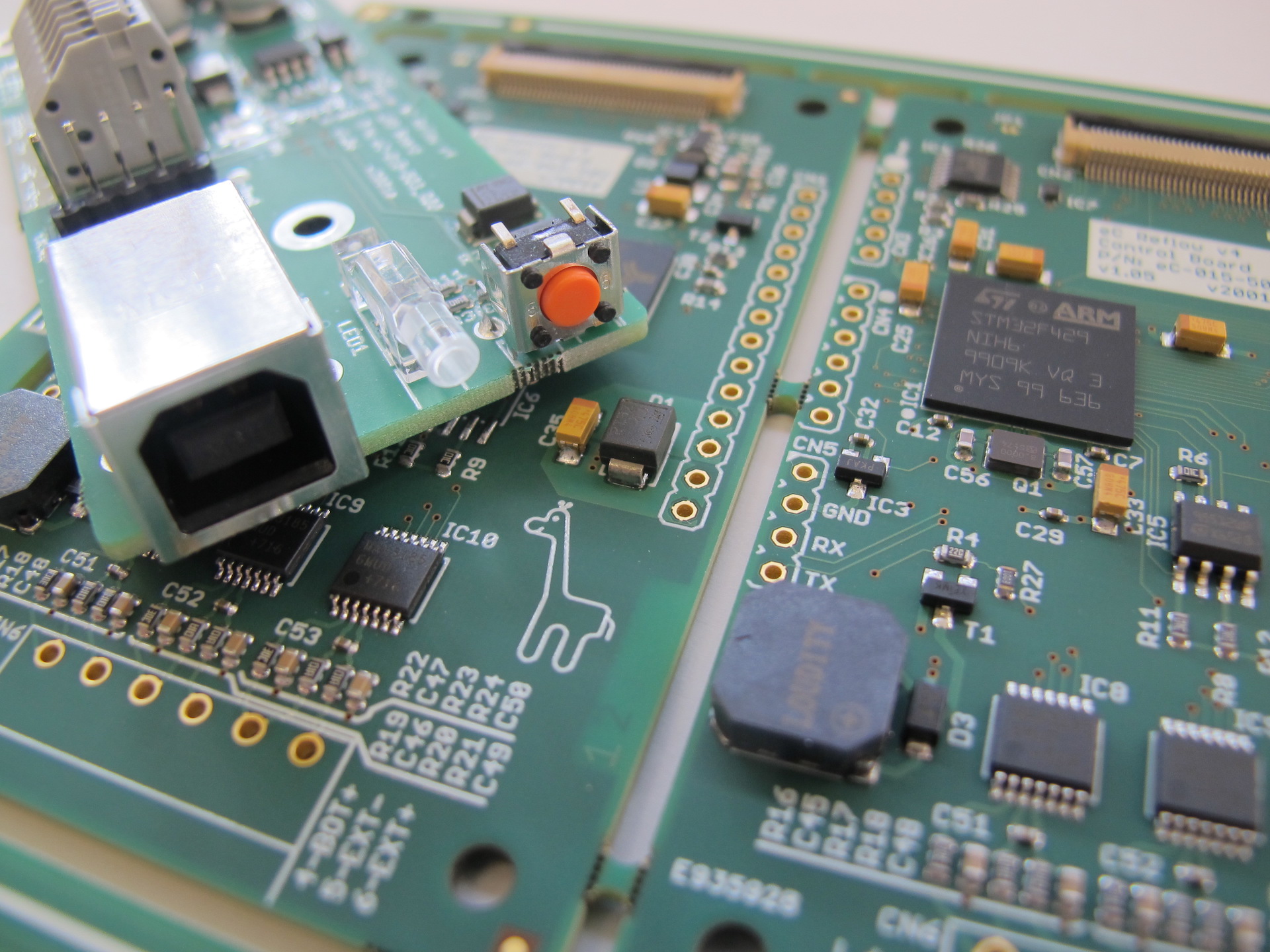

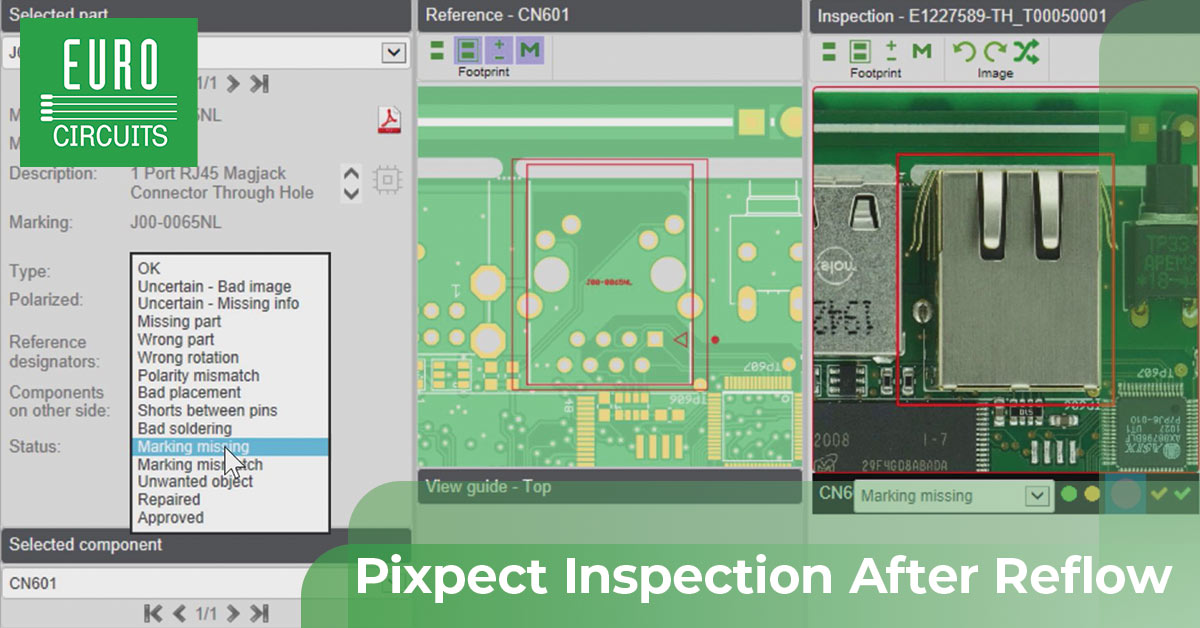

This is how Pixpect works: Our employees take high-resolution images of each assembled PCB side and upload them to the system for production tracking. A reference image of the assembly produced virtually in advance serves as a comparison.

The images are opened for optical inspection in Pixpect's intuitive web interface. The interface automatically aligns all components next to each other in the same way and shows the operator superimposed images for precise alignment.

With Pixpect, we can quickly and reliably detect incorrectly placed components, evaluate solder quality based on the amount of solder and identify defects such as tombstoning or solder bridges. ????

?? Stay tuned! In this video we show the optical inspection in our PCB assembly with Pixpect:

https://www.eurocircuits.com/assembly-manufacturing-technology/pixpect-inspection-after-reflow/

#eurocircuits�#PCB�#pcbdesign�#pcbassembly�#pcbmanufacturing�#pixpect�#smtproduction