Lead Free PowerPlus 2.0 – Powerelements of the latest generation by Würth Elektronik ICS

Lead-free high-current contacts for PCBs from Würth Elektronik ICS

LF PowerPlus 2.0 – Powerelements of the latest generation

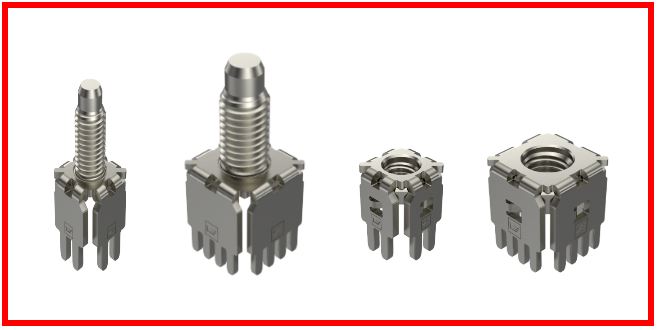

Würth Elektronik ICS, inventor of Powerelements for PCB contacting, presents a new generation of its proven, lead-free high-current contacts: the second PowerPlus generation, LF PowerPlus 2.0, has the same properties in terms of torque and current-carrying capacity as the previous version, but it is now even simpler and more efficient in terms of processing and assembly.

With the LF PowerPlus product family, Würth Elektronik ICS offers resilient and efficient high-current contacts for PCB contacting in press-fit technology applications. They are ideal for connecting components and cables to the PCB or as fastening elements, especially when high torques are required or little installation space is available.

Lead-free design and high torques

All LF PowerPlus high-current elements consist of a stamped brass base body (CuZn37) and a stainless steel screw element. The special design of the base body of the LF PowerPlus elements allows population on both sides in the same position, thus delivering a highly compact design. Important: All Powerelements do not contain any lead and are therefore not subject to any time-limited exemption regulation of the RoHS Directive.

The stainless steel screw of the LF PowerPlus Powerelements supports a higher tightening torque than other high-current contacts: from 1.8 Nm with the smallest thread, M4, up to 42 Nm with the largest version, M12. Depending on the layout, the LF PowerPlus high-current contacts can carry currents of up to 400 amperes.

Proven quality and new advantages in assembly

The new LF PowerPlus 2.0 series offers the same mechanical and electrical properties as its predecessor, but is substantially easier to process:

- The pin or nut is now firmly attached to the element, making automatic screwing possible.

- The new screw tip facilitates easier insertion and positioning of the nut.

- An improved pin design reduces the required press-in forces.

- Special press-in tools are no longer required.

LF PowerPlus 2.0 high-current contacts are available in sizes M5, M6 and M8, each as a socket or pin version. The dimensions M4, M10 and M12 can still be purchased as conventional variants. Changing over from the old to the new system is very simple: the elements are compatible with the old generation as regards their drilling pattern and height. LF PowerPlus 1.0 is therefore easily interchangeable with LF PowerPlus 2.0. Torque and current-carrying capacity also remain the same.

Designed in proven press-fit technology

Designed as press-fit elements, the new LF PowerPlus 2.0 power supply elements naturally have all the specific advantages of this technology: the PCBs are not exposed to temperature stress when the components are installed. The press-fit process is easy to integrate into the process chain. The press-fit is mechanically very stable and has an extremely low contact resistance of 100–200 ?Ohm.

Phase Control with Galvanic Isolation

Phase Control with Galvanic Isolation  De Itech IT6600C regeneratieve bi-directionele DC voeding

De Itech IT6600C regeneratieve bi-directionele DC voeding  New Phantom High Speed Camera Control software available

New Phantom High Speed Camera Control software available  SkelGrid 2.0: Flexible, Scalable, and Easy-to-Maintain with Integrated Master Controller and Modular Switchgear by Skeleton

SkelGrid 2.0: Flexible, Scalable, and Easy-to-Maintain with Integrated Master Controller and Modular Switchgear by Skeleton  Tektronix unveils SignalVu Spectrum Analyzer Software Version 5.4 for analysis of up to eight simultaneous signals

Tektronix unveils SignalVu Spectrum Analyzer Software Version 5.4 for analysis of up to eight simultaneous signals